© 2019 Wujiang Jinlan Machinery Manufacture Co. Ltd. All rights reserved.| Privacy Policy 苏ICP备14042212号| Terms and Conditions | Site Map Designed by iwonder.cn

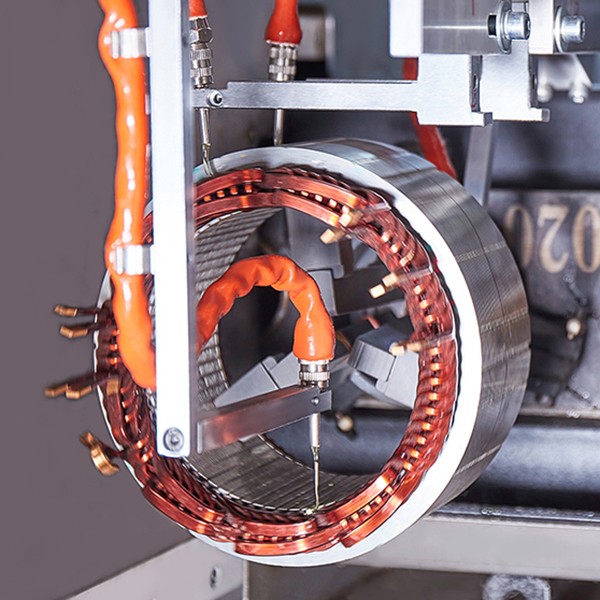

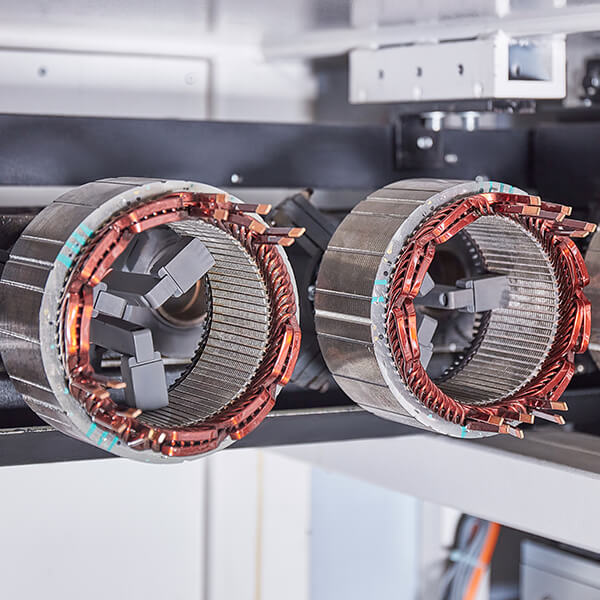

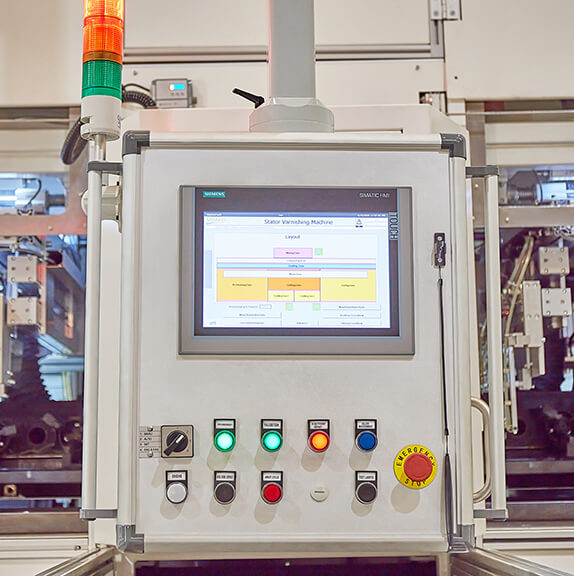

The trickling technology is used for the insulating treatment of stators to achieve the insulating function as desired. With multiple fixture design, this solution can realize fast model transfer. The automation, cycle time and trickling accuracy are adjustable based on the customer specifications. HMI is adopted for the machine operator to check product parameters and enable the robot to communicate with the other production lines both in front and at the back of the varnishing production line at the customer workshop.

multiple fixture |  data traceability |  quantitative control |

STATOR VARNISHING MACHINE TECHNICAL PARAMETERS

| Item | Technical Specification | Remarks | |

| Applicable product type | Flat copper wire/round copper wire | ||

| Heating temp range | Max 220℃ | ||

| Load/unload system | manual/robot | Can be connected with the production lines both in front and at the back | |

| Product clamping | Inner supporting/external clamping | To be designed according to the product model | |

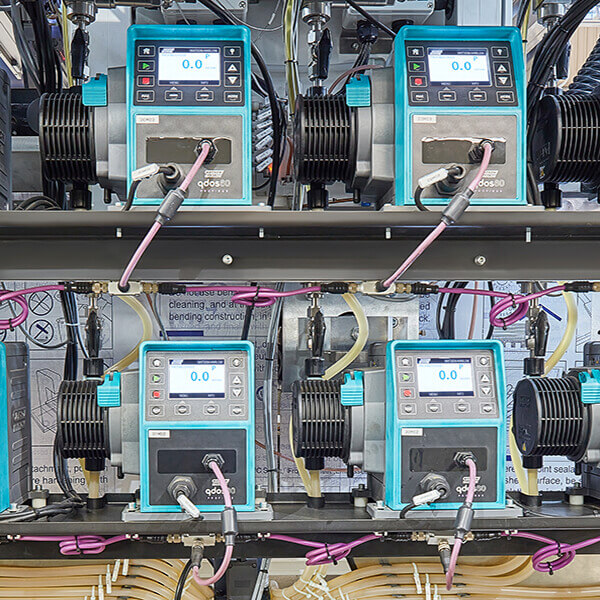

| Varnish type | Single component/two- component | ||

| Output accuracy | 1%-10% | Multiple configurations, to be designed based on customer specification | |

| Single machine cycle time | ≥45s | Depending on product model | |

FUNCTIONAL OPTIONS

| Item | Function Configuration | Remarks | |

Varnishing quantity monitor | ≥1g | Weight comparison before and after trickling process | |

Automatic model transfer | 3-shaft servo, nozzle position can be adjusted automatically | suitable for several product models | |

Varnish temp control | 10-50℃ | Varnish temp will be protected in heating and cooling working system | |

Flow rate monitor | pressure/flow rate monitor | Anti-clogging/fail-safe monitor | |

Data traceability control | code scanning/RFID | Database will be generated, to record process information, realize real-time data inquiry | |

Firefighting control | CO2 /water firefighting | Connected with the central firefighting facility at customer factory | |

Cooling system | Temp after cooling≤45℃ | external/built-in | |