© 2019 Wujiang Jinlan Machinery Manufacture Co. Ltd. All rights reserved.| Privacy Policy 苏ICP备14042212号| Terms and Conditions | Site Map Designed by iwonder.cn

The automatic equipment can be widely applied for both rotor insulation and rotor assembly,smart solutions for industries of automotive alternators. The cycle time and the working precision could be customized based on your technical specification. We offered complete technical services from plant investment planning,customized design to technical training and onsite commissioning for car alternator industry.

Used for rotor roll dipping with the resin after preheated of the car alternator rotor, to increase the insulating protection grade as desired, including varnish mixing system, roll dipping area, gelling and curing oven, cooling system. The equipment can realize fast model transfer, with multiple fixtures,catering to the market demands for multiple motor rotors.

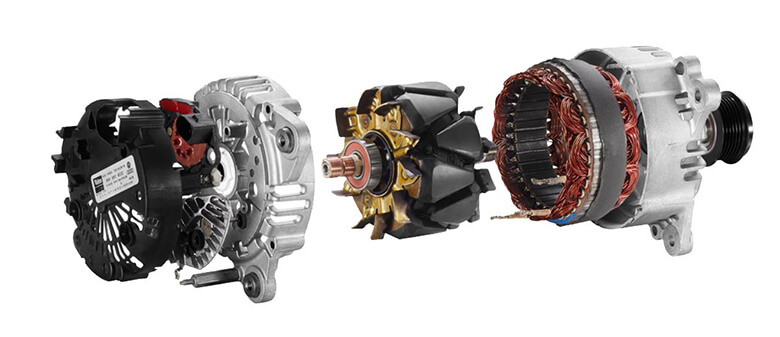

The rotor assembly line is adopted for magnetizing, general assembling and performance inspection, to improve the efficiency and quality for generator rotor industry. It is featured with functions of resistance inspection, shaft input, collector ring fit-pressing, coil cutting and hooking, welding and electrical performance test of alternator rotors,a smart solution for car alternator industry.