© 2019 Wujiang Jinlan Machinery Manufacture Co. Ltd. All rights reserved.| Privacy Policy 苏ICP备14042212号| Terms and Conditions | Site Map Designed by iwonder.cn

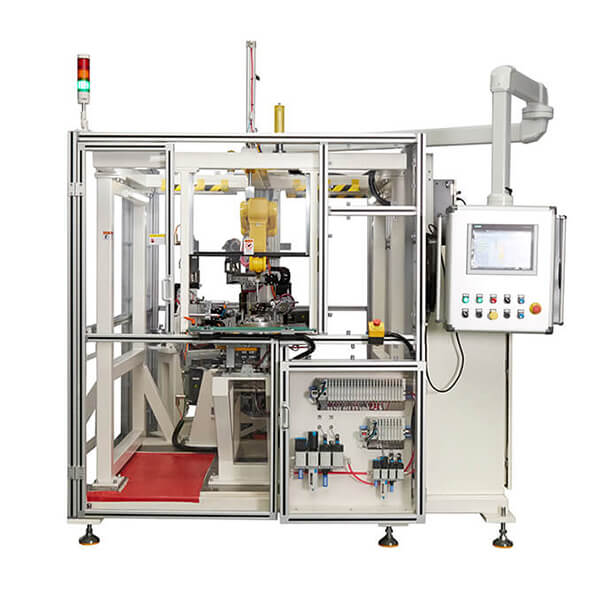

The equipment for stator industry adopts intelligent data traceability system, can realize fast model transfer with multiple ways of clamping. The cycle time and the production precision could be customized and designed based on your technical specification. Possibe to communicate with the other production lines both in front and at the back of the varnishing line at customer's worksite.

Used for varnishing at the electric motor stator winding, widely applied for insulating treatment of different models of motor stator. It boasts of precise quantity control and automatic nozzle position adjustment on alaternator stator. The production line includes material mixing system, preheating oven, servo trickling system, gelling, curing, and cooling system, HMI, etc.

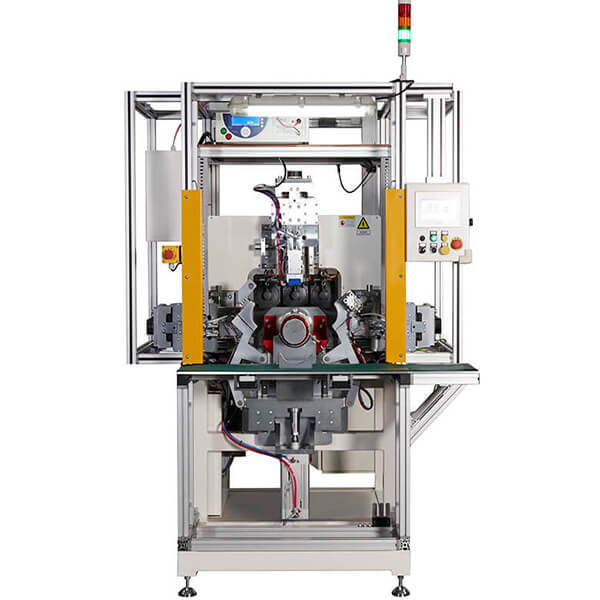

Finish high-frequency burning, auto wire brushing, lead wire cutting, 2-station tin coating and visual inspection at one stop,a comprehensive solution for motor and stator industry. Featured with high precision and intelligent workflow control,a smart solution for alternator stator industry.

OTHER AUTO WORK STATIONS

Stator Lacing Machine The robot pre-finishes lead wires before automatic lacing by servo system and thread cutting of the motor stator. The servo system is compatible with multiple product models of motor and stator, thus realize flexible model transfer. |  Stator Test Machine This stator tester does the test on multiple parameters of the motor stator with data records, making judgement on electrical performance. It is integrated with functions of both wire cutting and finishing of the electric motor stator winding. |